Outline of Awamori Making

- Home

- Outline of Awamori Making

Awamori production process

- Ingredients

- The basic ingredient of making Awamori is Indica rice from Thailand.

- Washing, soaking, steaming

- The rice bran is rinsed thoroughly to absorb water and then steamed.

- Making koji

- Black koji mold and water are mixed with steamed rice to make rice koji.

During the process that takes two days, close attention must be paid to the temperature and water content.

- Moromi

- Awamori yeast and water is added to rice koji to make moromi that is fermented for 19 days.

- Distilling

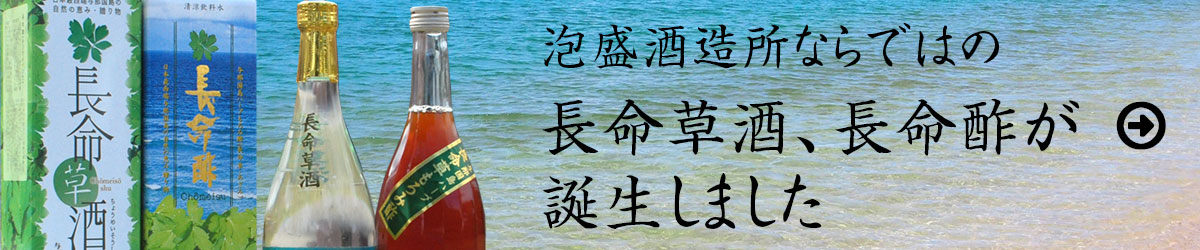

- Once the moromi is ready, Awamori is distilled in a pot still. Sakimoto Sake Distillery uses the traditional direct-fire heated still that concentrates the flavor components of moromi, resulting in a richly-flavored product. The first liquor coming out from the still is called “Hanasake (Flower Liquor).”

- Filtration

- Distilled Awamori is immediately filtered to remove excess oil and other substances that cause unpleasant taste.

- Storage aging

- Filtered Awamori is aged in storage vessels.

The longer Awamori ages, the more mellow the taste.

- Bottling

- Aged liquor is bottled, carefully labeled one by one by hand, packed in a box, and shipped.

Old-fashioned pot still production process

The mash is poured into the pot that is fired up to start the distilling.

The mash is stirred continuously manually to avoid the mash burning while the still heats up.

When steam and liquor scent start rising from the still, the pot’s lid is closed.

As the steam rising from the mash boiling in the pot is cooled, “Hanasake” and Awamori will drip out drop by drop.

Distilling in process.

The different lid shape of the left and right pots results in a subtle change in taste and aroma.

After the distillation is finished, the pipe is removed from the liquor tank.

The pot’s lid is opened, and the sake lees remaining in the pot are removed to complete the work process.